Application

They are used to separate aggregates in 'dry' or 'wet' processes.

'Dry' process - requires additional processing of the product in washers.

'Wet' process - its effect is a final product that generally does not require additional processing.

Additionally, high-performance expansion boxes can be installed, enabling easy direct connection of the dredger and feeding of the excavated material directly to the screen, additionally equipped with a large sieve deck, which allows for the initial removal of sand fractions along with excess water.

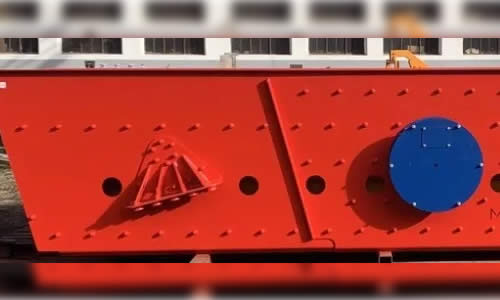

Construction

The sieve is made of quality materials welded using Mig/Mag technology and riveted using the HUCK-BOLT technique - which ensures a durable and practically indestructible connection.

The decks can be equipped with polyurethane sieves in the four most popular mounting systems, or with steel sieves.